Berman Brothers acquired Rubin Iron Works in 2005 to offer the full spectrum of metal services.

For more than 100 years Rubin Iron Works specialized in carbon and alloy steel fabrication. Today we specialize in press braking, rolling, forming, shearing, punching, cutting and welding.

For more than 100 years Rubin Iron Works specialized in carbon and alloy steel fabrication. Today we specialize in press braking, rolling, forming, shearing, punching, cutting and welding.

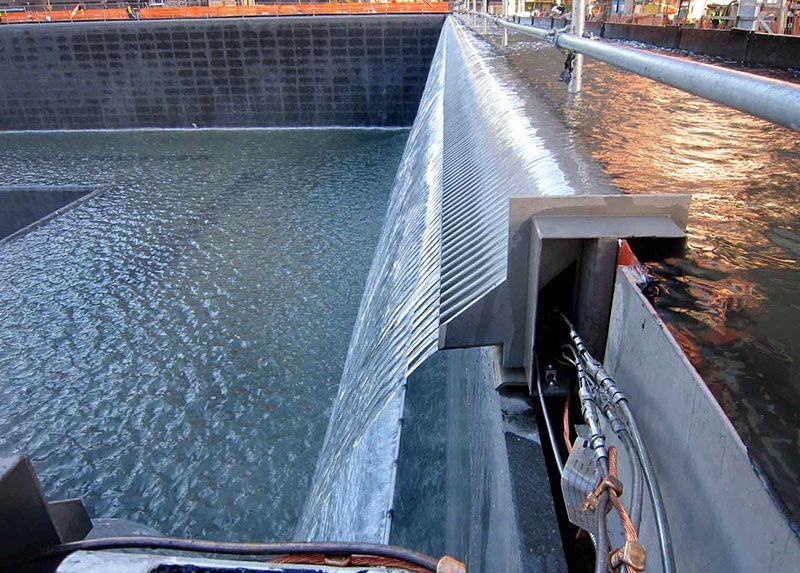

Our skilled steel fabricators are leaders in custom fabrication. We use precision technology and AWS Certified Welders to create and finish your custom metal fabrication to spec. Berman Brothers can fabricate any mechanical, structural or ornamental metal element and is the only facility in Florida that can provide heavy rolling services.

Our experienced estimators and certified welders have great diversity of skill in fabricating tanks, hoppers, handrails, stairs, landings, mitered elbows, cones, conveyer parts, weldments, and any custom fabrication job you need.

Our full-service fab shop not only offers four different cutting methods, but also has the largest waterjet available in Florida and Georgia. Because of our focus on technical skill and customer service, we can handle quick turnaround times and highly specialized requests.

Fabrication Equipment Capabilities

- Cutting – Water Jets and Plasma

- Shearing – 12′ Wide Up To 5/8″ Thickness A36 Plate

- Welding – Carbon Steel, Stainless Steel, Aluminum (Mig, Tig, and Flux Core)

- Braking

- Forming

- Punching

- Rolling (Manual and Automated)

- Angle

- 8″ x 8″ x 1″ Leg In-Leg Out. Min Outside Radius 120”

- 5″ x 5″x 5/8″ Leg Out. Inside Diameter 60”

- 5″ x 5″x 1/2″ Leg In. Inside Diameter 70″

- Channel

- C9 x 25.4 Leg Out. Inside Diameter 45″

- C9 x 25.4 Leg In. Inside Diameter 50″

- C6 x 18 Hard Way. Inside Diameter 240″

- C18 x 58 Leg In-Leg Out. Min Outside Radius 60″

- Beam

- S8 x 23 Easy Way. Inside Diameter 40″

- S6 x 17.25 Hard Way. Inside Diameter 150″

- S12 x 35 Min Center Line Radius 48″

- WF6 x 16 Easy Way. Inside Diameter 44″

- Plate

- A36 5/8” thick x 10’ wide plate to 18” Inside Diameter

- A36 1” thick x 8’ wide plate to 48” Inside Diameter

- Angle

Welding Certification and Qualifications

Berman Brothers offers many welding procedures, welder qualification, and welder certification capabilities helping our customers confirm their welders and welding procedure are in accordance with specific codes and standards typically American Society of Mechanical Engineers (ASME) and the American Welding Society (AWS). Berman Brothers can test all aspects of welding procedures and welder performance qualifications by conducting bend testing.

Berman Brothers welders deliver quality workmanship utilizing welding process (SMAW, FCAW, GMAW, and GTAW).

Types of Certifications and Qualifications: Pipe and Plate

- Fillet

- Groove

- Flat 1F and 1G

- Vertical 2F and 2G

- Horizontal 3F and 3G

- Overhead 4F and 4G

- All 6G – Pipe Only 45-degree angle in position

Weld Testing of Coupons : Pipe and Plate

If you are interested in welding certification services, please let us know.

I have been working for JEA at the Northside Generating Station for 11 years as a Mechanical Technician. When I was on my tools, we put together materials that had been Plasma Cut and rolled by Rubin Iron Works. I can say that it is a pleasure working with materials that fit together like a puzzle. I highly recommend them for all your fabrication needs.

AMAZING. As someone that knows nothing about metal, they held my hand and always made me feel comfortable. From our initial phone call, to making sure we placed the perfect order, to picking up at their location…it was all roses. I’m super happy.